Infrastructure IoT’s Vista Data Vision Supports Critical Sydney Tunneling Project with Automated Monitoring

Creating a More Accessible, Livable City

Building Transport for NSW’s M6 Stage 1 motorway in Sydney has been discussed since the 1950s, and in 2019, the project received planning approval. In 2021, CIMIC Group’s CPB Contractors and UGL, in a joint venture with Ghella (CGU), were announced as the delivery partners to design and build the M6 Stage 1.

The M6 Stage 1 will provide a “missing link” by connecting the city’s south to its larger motorway network. The AUD 3.1 billion project features a northbound and a southbound tunnel—each around 4 kilometers long—and pathways for pedestrians and bicyclists. Built mainly underground, the M6 will contribute to a more accessible and livable city, reducing congestion, improving travel time, and diverting more than 2,000 trucks a day from surface roads. The M6 Stage 1 is expected to open to traffic in late 2025.

Better Data, Better Decision-making

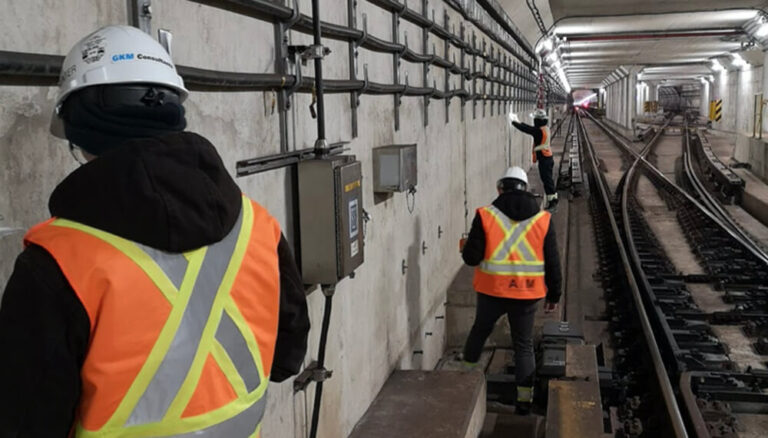

The project needed advanced underground monitoring for their focus on public safety and the protection of the surrounding environment during the motorway’s construction. They selected Tetra Tech Coffey, a leading provider of consulting and engineering services worldwide, to design, implement, and oversee a remote, automated monitoring system.

As part of its solution, Tetra Tech Coffey chose Infrastructure IoT’s Vista Data Vision for its powerful capabilities around data storage, analysis, reporting, and visualization. This robust, locally hosted software empowered Tetra Tech Coffey to securely capture, analyze, and share reliable, real-time sensor measurements, such as pore water pressure and lateral displacement.

“Because of our experience with Bentley platforms, we’re very comfortable with the technology, and it was a great fit for geotechnical data,” said Luke Young, an associate engineering geologist at Tetra Tech Coffey’s Sydney office. “Our experience told us we could present an effective dashboard, create daily reports, and initiate alarms based on trigger thresholds.”

With instant, remote access to the sensor data, Tetra Tech Coffey saw real-time data analyses and insights that could easily be shared with stakeholders for better collaboration and decision-making. With custom alarms and notifications, Tetra Tech Coffey was immediately notified if sensor readings were outside of the normal range, empowering them to make well-informed critical decisions quickly and with confidence.

“Our experience told us we could present an effective dashboard, create daily reports, and initiate alarms based on trigger thresholds.”

-Luke Young, Associate Engineering Geologist, Tetra Tech Coffey

Richer Data, Simplified

From internal geological design engineers to external excavation and construction contractors, there were many stakeholders who needed visibility into the sensor data readings.

“There are quite a few professionals interested in viewing the sensor data and monitoring what’s happening for different purposes,” said Young. These purposes include daily reviews by multiple tunneling teams and as part of the approvals process for tunneling permits.

With Infrastructure IoT’s Vista Data Vision platform, Tetra Tech Coffey clearly presented the sensor data in streamlined reports and dashboards that were easy for all stakeholders to understand. According to Young, “It provides greater confidence in decision-making when they can log on and see the data in real time.”

The customized daily reports also gave stakeholders actionable insights that save time and money and increase efficiency. “Key to what we’re trying to do is not overcomplicate things,” said Young. “That’s why having a geotechnical consultancy like ours look after this data is important; we understand what the decision-makers are trying to see. With this platform, we’re able to present the most important information to them.”

A Single, Secure Data Source

Tetra Tech Coffey securely captured and stored monitoring data using Infrastructure IoT’s Vista Data Vision, which now serves as the single source of truth and is accessible to all stakeholders who need it.

“Often what happens is that data goes missing, or someone doesn’t have access to it, or no one knows where it is,” said Young. “And often, the team that collected the data is not the same as the one doing sensor installation or data monitoring, so those two sets of information are separate; they never come together.”

In addition to tunnel monitoring, Tetra Tech Coffey also provided a number of other services on the M6 project, including the initial subsurface site investigation. Excerpts of this can be added to the Vista Data Vision platform and are valuable in combination with ongoing condition monitoring data streams.

“We were able to bring our observations from the field into the platform, overlay our sensor data, and present them on graphs to better represent what’s happening underground,” said Young. “We can bring it together in one place so people can make better-informed decisions.”

“We were able to bring our observations from the field into the platform, overlay our sensor data, and present them on graphs to better represent what’s happening underground.”

-Luke Young, Associate Engineering Geologist, Tetra Tech Coffey

Looking Toward the Future

Digital applications are rapidly transforming engineering fields, including critical infrastructure and construction, and Tetra Tech Coffey has been a keen adopter of emerging technologies.

Looking toward the future, Young said that they see great potential to bring digital twin technology, such as Bentley’s iTwin, to all project stages, from investigation and design to construction to asset management.

“This is the future,” said Young. “And it is exactly where our business is headed.”

He is excited about the potential to use the iTwin Platform for long-term maintenance programs, integrating sensor readings of all types, including geotechnical, structural, and environmental, with other data sets, as well as seamlessly integrating with other digital tools.

“We are not software developers. We like to leave the software development to the experts,” said Young. “Bentley is strong in that space. We value their service, and they have put us in a strong position for the future.”